Laser marking is a high-precision, non-contact processing technology that uses a high-energy laser beam to burn or etch permanent marks on the surface of a workpiece. Depending on the material, applications can be further categorized into metal marking, glass marking, plastic marking, ceramic marking, and more.

Laser marking is based on localized energy delivery. A focused laser beam heats the material surface precisely, causing controlled changes without physical contact or mechanical stress.

The process starts with a laser source—commonly fiber, CO₂, or UV lasers depending on the application and material. The laser beam is directed by a galvo scanner system, which uses fast-moving mirrors to steer the beam along programmed paths across the workpiece surface.

Laser marking demo

Compared to mechanical systems, galvo-driven beam control enables rapid repositioning, often completing complex marking patterns within seconds. This efficiency makes laser marking ideal for automated production lines where both speed and repeatability are crucial.

Moreover, manufacturers can precisely control the mark’s depth, color, and shape. For instance, a short, high-frequency pulse can induce shallow surface discoloration (annealing), while higher power with slower pulses can engrave deeper structures.

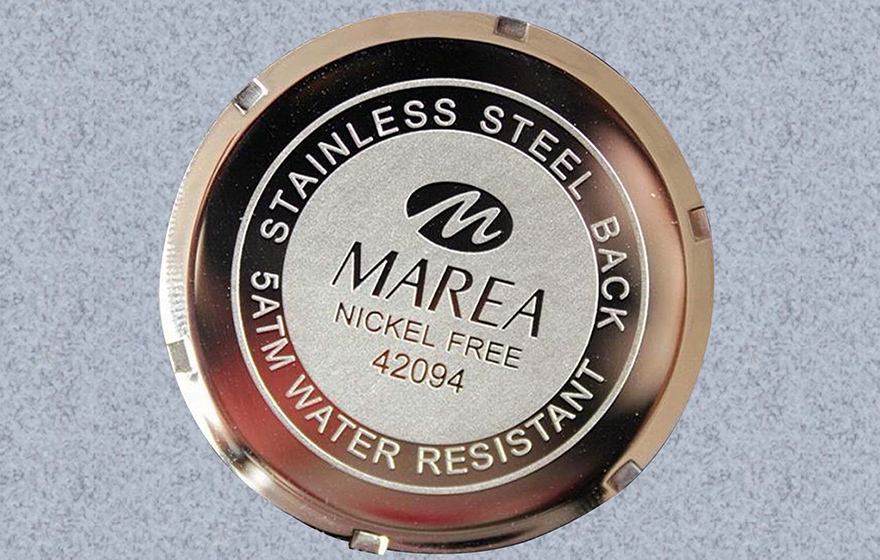

Laser marking finds extensive use in modern industrial manufacturing, spanning metal parts to consumer goods. From serial numbers on automotive engines and QR codes on battery cases to brand logos on electronic device housings, laser marking provides clear, durable, and eco-friendly solutions.

Auto parts laser marking

Laser marking system can rapidly and accurately mark metals, plastics, ceramics, and more—meeting industry needs for traceability, functional labeling, and customization in mass production. Especially in automotive, aerospace, electronics, medical devices, and energy sectors, laser marking has become indispensable for product tracking and brand enhancement.

Laser marking enable microsecond-level beam movement, greatly boosting marking throughput compared to mechanical XY stages, ideal for high-volume manufacturing. They offer micron-level positioning accuracy and real-time feedback, ensuring consistent mark quality across thousands of parts.

Galvo-based systems are compatible with metals, plastics, ceramics, and composites, adjusting laser parameters to optimize marking without substrate damage. The non-contact nature of laser marking minimizes wear and reduces maintenance costs, while seamless integration with robots, vision systems, and MES enables fully automated workflows.

Additionally, laser marking is an environmentally friendly process, eliminating inks, solvents, and abrasives, producing clean marks with minimal waste.

Laser marking is rapidly evolving from a basic identification method into a cornerstone of smart, automated, and green manufacturing. It delivers precise, durable, and contact-free marking solutions across industries like automotive, electronics, batteries, and medical devices.

As production demands faster throughput and enhanced traceability, laser marking is increasingly integrated with robotics, vision systems, and real-time data monitoring, aligning perfectly with the future of intelligent and sustainable manufacturing.

1. How do I choose the right laser source for my marking application?

The selection depends on the material and the required marking effect. Fiber lasers are ideal for metals, UV lasers excel at plastics and glass with minimal heat impact, CO₂ lasers work well for organic materials, and infrared lasers support general industrial marking. Factors such as depth, contrast, speed, and thermal sensitivity should also be considered.

2. Can laser marking be integrated into automated production lines?

Yes. Modern laser marking systems support integration with conveyors, robotic arms, vision systems, and MES/ERP platforms. Through standardized communication protocols and control cards, manufacturers can achieve inline marking, batch traceability, and fully automated workflows.

3. What maintenance is required for a laser marking system?

Laser marking systems require minimal maintenance. Routine checks typically include cleaning the optical path, verifying lens condition, inspecting the galvo scanner, and ensuring proper cooling. Fiber and UV laser sources generally have long service lives and do not require frequent calibration.