Laser welding systems provide a precise and efficient method for joining materials by focusing a high-intensity laser beam to melt and fuse metals along a controlled seam. Compared to traditional welding, laser welding offers cleaner joints with minimal heat-affected zones, deeper penetration, and excellent repeatability. These characteristics make it especially suitable for demanding manufacturing sectors such as automotive, electronics, battery production, and medical devices. Modern laser welding setups commonly utilize continuous wave or pulsed fiber lasers compatible with various metals including stainless steel, aluminum, and copper.

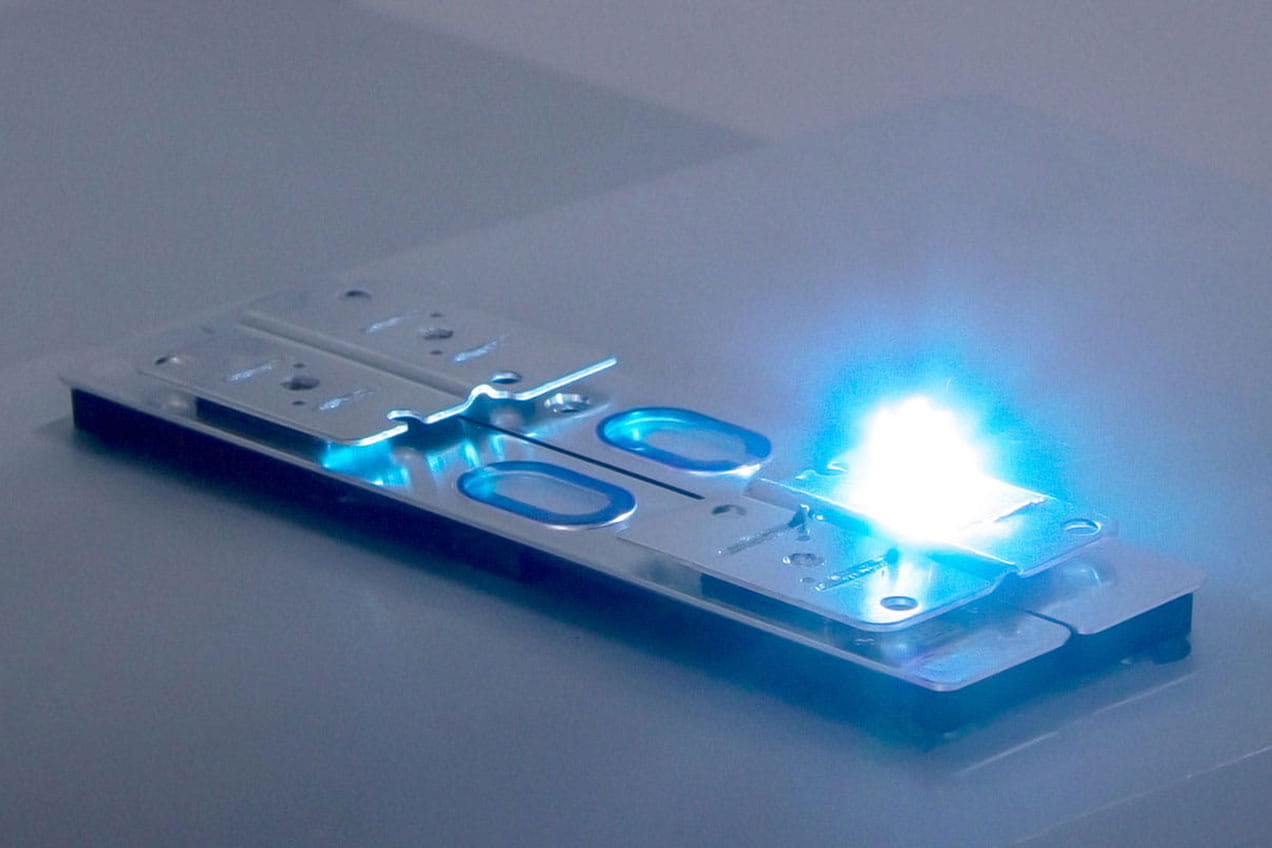

Galvanometer-based laser scanning technology plays a critical role in advancing laser welding system. Galvo scanners use fast, precise mirrors controlled by high-speed motors to steer the laser beam across complex welding paths without physically moving the workpiece or laser source. This digital beam steering enables rapid positioning, multi-spot processing, and intricate weld patterns with high accuracy and repeatability. When combined with dynamic focusing modules, galvo scanners maintain consistent spot size over uneven or 3D surfaces, providing superior control in automated laser welding systems, robotic cells, and multi-axis platforms.

Laser welding with galvanometer scanners is widely adopted across industries requiring high throughput and tight quality control. In automotive manufacturing, it facilitates the joining of battery modules, body panels, and powertrain components with minimal distortion and high strength. Electronics manufacturers leverage it for delicate micro-welding of sensors and housings, while medical device production benefits from its clean, contactless operation on instruments and hermetic seals. Key advantages include high welding speed, low thermal impact, and seamless integration with real-time process monitoring and automation technologies, making it ideal for scalable, precise manufacturing.

Scanner Optics’ high power galvanometer welding systems combine speed, precision, and safety to meet industrial production needs. Featuring high-speed digital galvanometers capable of welding speeds up to 3000 mm/s, these systems significantly boost throughput while ensuring consistent weld quality. A closed-loop control provides real-time position feedback for stable beam steering, even during complex or high-speed motion. Safety mechanisms, such as an automatic laser shut-off within 10 milliseconds upon detecting anomalies, protect operators and equipment. Designed for durability and ease of integration, these systems excel in automated manufacturing environments where precision and safety are paramount.