In modern laser processing, applications such as laser marking, engraving, and cutting have become widely used across industries including manufacturing, electronics, medical, and automotive. Achieving high-precision, high-efficiency processing depends not only on high-quality lasers and optical systems but also on core control hardware—laser controllers. Acting as the "brain" of the entire laser system, these controllers convert operator commands into precise control signals, coordinating the laser, laser galvanometer, and other peripheral devices to improve processing accuracy and system stability.

A laser controller is the core module of a laser scanning system. By executing pre-programmed control routines, it dynamically manages the laser’s output power, repetition rate, operating mode, and beam movement path. It converts design software instructions, such as vector graphics or patterns, into precise laser motion and switching commands. The controller can also adjust the beam’s size, shape, and position in real time, ensuring that the processing results meet design specifications.

One of the primary functions of a laser controller is to manage the laser itself, including starting and stopping the laser, adjusting power, and controlling frequency and beam position. It also monitors the laser in real time, allowing precise adjustments of output parameters such as beam size, shape, and operating mode.

The controller converts design files from marking software into a series of precise motion instructions and laser control signals. These commands guide the laser beam across the work area to create the desired patterns, text, or marks.

The controller sends signals to coordinate X and Y-axis movements of the galvanometer, ensuring the laser follows the intended marking path. The controller’s precision and response speed directly determine marking speed and accuracy.

Laser controllers receive data from the computer or marking software, process it into marking paths and actions, and provide real-time feedback on operational status, including errors or warnings, so operators can monitor and adjust the process.

Safety is critical in laser operations. Laser controlers include safety alarm functions in two categories: alarms for the laser itself (e.g., collision, short circuit, overheating) and alarms for peripheral devices. By connecting external IO devices, the controller can monitor the status of supporting equipment such as chillers or gas cylinders.

Depending on functionality and application, laser controllers are typically classified into:

Manage mechanical platforms or multi-axis systems, performing motion interpolation and trajectory control. Suitable for industrial equipment requiring high positional accuracy and synchronized motion.

Focus on laser switching, power modulation, and output timing. They are the core modules for galvanometer-based laser marking, engraving, and cutting systems.

Designed for high-speed galvanometers, achieving precise synchronization between laser and galvo position. Widely used in micro-processing, welding, and laser cleaning.

Combine motion control, laser control, and IO management on a single hardware platform, ideal for standardized equipment and mass production, simplifying system integration and deployment.

When selecting a laser controller, consider:

System Stability: Laser systems often operate continuously at high intensity, making long-term stability essential.

Operating Speed: Fast computing and response speed are critical for processing efficiency.

Core Features: Choose a controller with functions matching your application, such as vision recognition, multi-head control, or precision processing.

Budget: Prices vary significantly by brand and configuration, so select based on budget and actual needs.

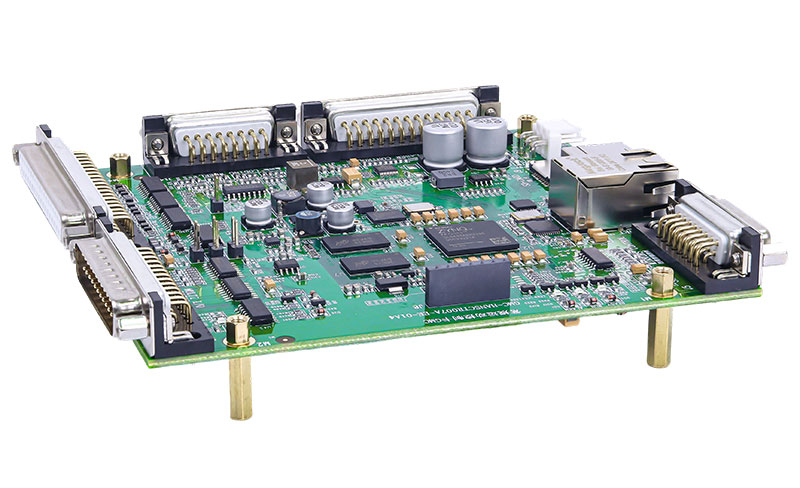

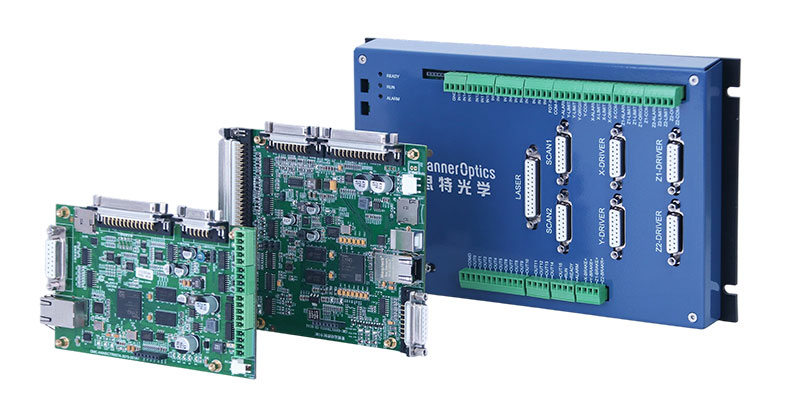

The GMC laser control card was developed based on real-world system integration experience, with a focus on system stability, protocol compatibility, and deployment efficiency. It is not designed to replace general-purpose controllers but serves as an optimized solution for galvanometer-based systems requiring high consistency and long-term reliability.

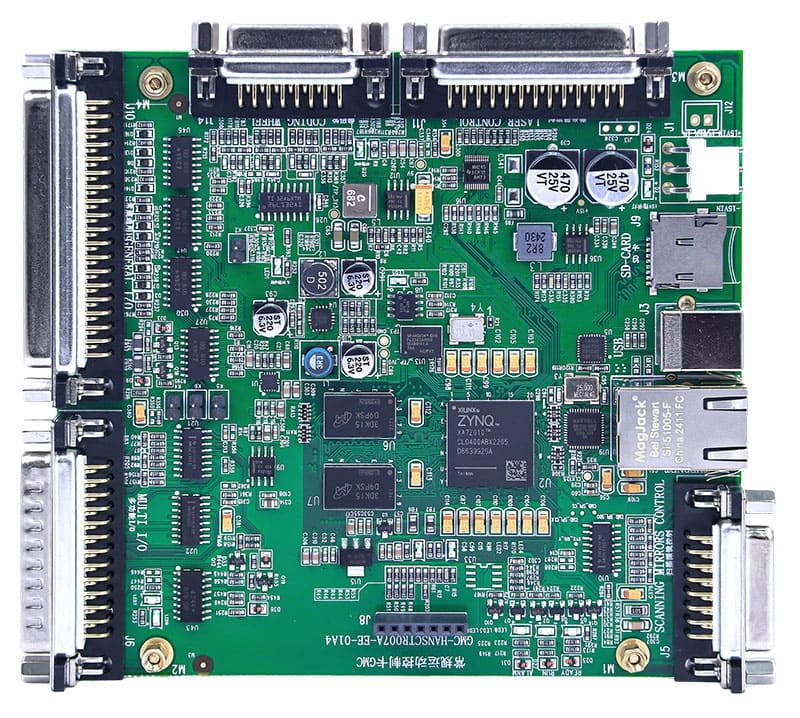

Key features of the GMC laser control card, developed by Scanner Optics, include:

1. Supports 2D, 3D, and flying marking functions.

2. Compatible with three galvanometer data communication protocols: XY2-100, SPI, and ST2-100. Users can switch protocols via host software as needed.

3. High-speed Ethernet communication with marking software improves data transmission and marking efficiency. Only the computer IP needs to be configured; no other setup is required.

4. Provides demo programs in C++ and C#, allowing users to develop based on their preferred programming language.

5. Supports fiber lasers, CO2 lasers, UV lasers, and green lasers.

6. Includes high-precision calibration software; once calibrated, it can be used permanently. The calibration file is stored on the controller, preserving data after power-off without the need for repeated loading.