Laser ablation is a precise, non-contact material processing technique in which a high-power laser beam is focused on the surface of a material. When the laser energy density exceeds the material's ablation threshold, the irradiated material is rapidly removed from the surface with minimal mechanical contact, undergoing vaporization, sublimation, or plasma ejection in an extremely short time.

Due to its high precision, controllability, and minimal heat-affected zone, laser ablation is widely used in industrial manufacturing, electronics, medical devices, and scientific research.

In industrial laser ablation applications, the performance of a laser ablation system depends not only on the laser itself but also on the scanning method, focusing optics, and motion control accuracy, which often play a decisive role in processing quality and efficiency.

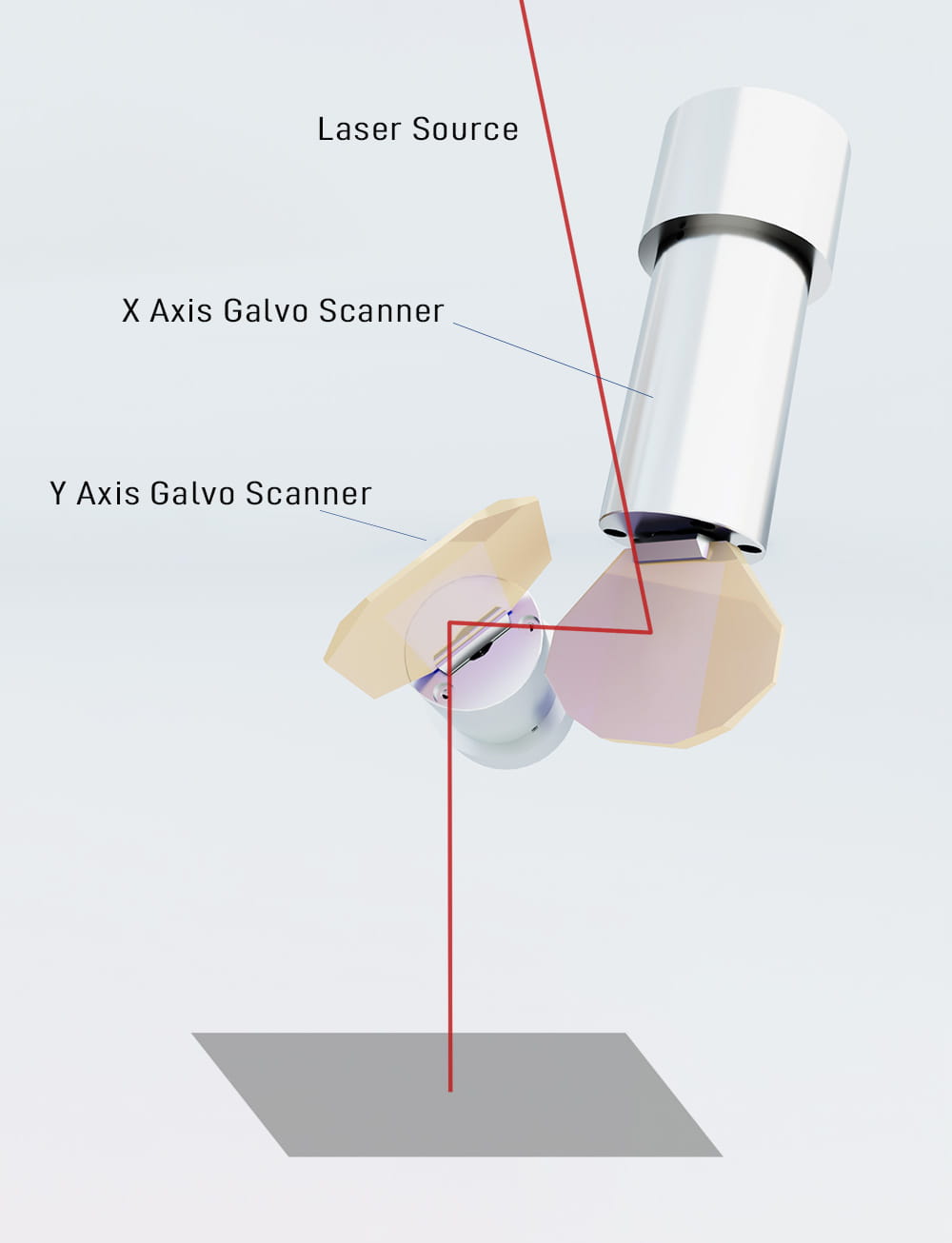

A typical laser ablation system consists of the following main components:

1. Laser Source: Common options include ultraviolet (UV), green, infrared (IR).

2. Beam Expander and Other Beam Shaping & Delivery Optics

3. Laser Scanning System.

4. Laser Control Card and Processing Software.

Among these, the laser scanning system is the key component. It controls how the laser beam moves across the workpiece surface, directly affecting processing efficiency, precision, and consistency. Optimizing the scanning system can significantly enhance the performance and results of laser ablation.

In industrial applications, in addition to fixed-point ablation, laser ablation is mainly performed using two methods: galvo scanning ablation and polygon scanning ablation.

Galvo scanning uses a galvo motor to control the mirror's movement along the X and Y axes, enabling precise deflection of the laser beam across the processing plane. It is currently the most widely used scanning method in laser ablation systems.

This method supports arbitrary vector and fill scanning paths, offers high positioning accuracy, excellent repeatability, and fully programmable trajectories. When combined with a 3D dynamic focusing system, it allows precise control of ablation depth and energy density, making it ideal for complex patterns and functional structures.

In applications with strict focus requirements or varying surface heights, the 3D dynamic focusing galvanometer system can adjust the Z-axis in real time. This ensures consistent spot size and energy density across the entire workpiece.

Galvo scanning is therefore highly versatile and especially suitable for high-precision, fine-featured laser ablation tasks.

Polygon mirror scanning uses a high-speed rotating multi-facet mirror to produce continuous line scanning. Its scanning speed is much higher than that of traditional galvanometer systems.

This method is characterized by extremely high scanning speed and line-based scan trajectories, but its flexibility in path design is limited. It is typically used for ultra-fast line scanning, imaging, inspection, and display-related applications.

In laser ablation, polygon scan is suitable for tasks that demand very high speed with relatively simple patterns.

For more complex 2D designs or precision functional processing, polygon scanning often needs to be combined with additional motion axes or hybrid scanning solutions to achieve higher accuracy and more advanced processing capabilities.

Laser ablation serves as the foundation for various applications, including laser cleaning, laser marking, and laser texturing. It offers non-contact processing, high precision, minimal heat-affected zones, and easy integration into automated systems, making it widely used in advanced manufacturing and high-precision processing.

Laser cleaning uses laser ablation to efficiently remove surface oxides, oil, rust, and coatings without chemical reagents or consumables. It provides excellent selectivity and repeatability, making it ideal for cleaning and surface preparation tasks that require high surface quality. Typical applications include automotive manufacturing, mold processing, aerospace, and precision machinery.

Laser Ablation Cleaning for cylindrical battery

Laser marking employs laser ablation to remove a small amount of material from the surface, creating high-contrast, permanent marks. This process is stable and reliable, suitable for industrial markings such as QR codes, serial numbers, and functional area identifiers. It can produce high-resolution and wear-resistant marks on metals, ceramics, and some plastics.

Laser marking for Nameplate

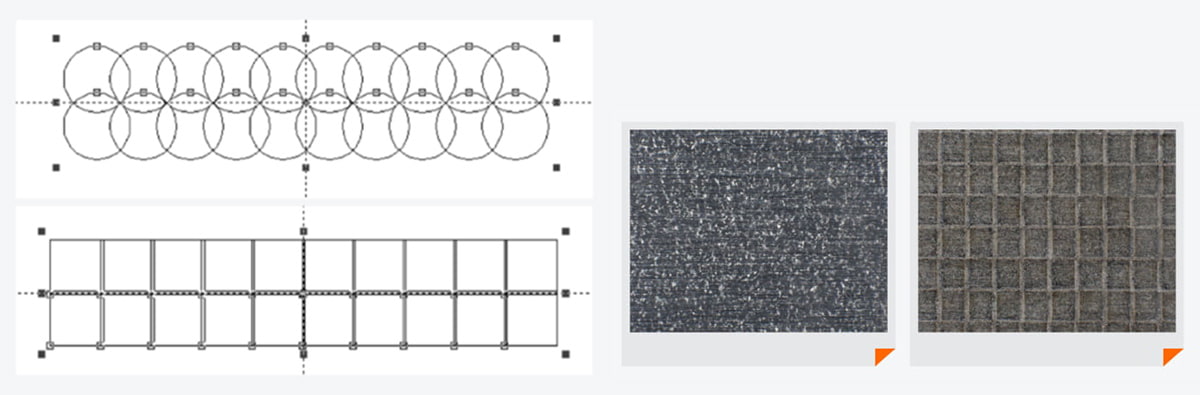

Laser texturing creates micro- or nano-scale patterns on the material surface, typically using circular or square laser spots, which allows precise control of surface roughness for both functional and decorative purposes. This technique is widely applied to optimize friction performance, enhance adhesion, and improve surface aesthetics.

Compared to a circular laser spot, a square laser spot effectively reduces the spot overlap rate.

| Comparison | Laser Ablation | Laser Engraving |

| Processing Depth | Extremely shallow (micron or nanometer level) | Removes more material, up to millimeter level, creating grooves |

| Technical Principle | High-energy laser melts the surface layer, causing color change or slight protrusion | Laser removes material, forming noticeable recessed 3D features |

| Applications | High-precision surface marking, such as electronic component codes or instrument scales | Applications requiring 3D effect, such as crafts or mold processing |

| Process Differences | Simple process, minimal impact on internal material structure, smooth edges | Complex process, may produce burrs or alter material structure |

Overall, laser ablation is better suited for micro-precision marking and functional surface modification, while laser engraving is more suitable for creating 3D shapes and deeper material removal.