Choosing the right galvo scanner is essential for achieving high-quality results in laser marking, engraving, cutting, welding, cleaning, and micromachining. While most galvo scanners look similar from the outside, basically a motor with a mirror, their internal optical design, dynamic performance, and precision can differ a lot. This article breaks down the core parameters you should evaluate, which may assist you in choosing the appropriate galvo scanner.

These parameters determine which lasers and optical systems the galvo scanner can be matched with.

The aperture refers to the clear diameter of the mirro area through which the laser beam can pass. It must be larger than the beam diameter. Common sizes include 7 mm, 10 mm, 14 mm, 20 mm, 30 mm and 50mm.

The operating wavelength determines the type of coating the scan mirrors must use. You need to choose a high-reflectivity coating (>99.5%) that matches your laser wavelength—otherwise the mirror may burn. Typical coating options support fiber lasers (1064 nm), green lasers (532 nm), UV lasers (355 nm), and CO₂ lasers (10.6 µm).

The scan angle is the maximum mechanical deflection angle of the mirror, usually expressed as ±θ (e.g., ±20°), and sometimes in radians (1 rad = 57.3°). Some manufacturers also list the optical scan angle, so make sure to confirm which one is used.

Because the reflection angle doubles when the mirror rotates, an optical scan angle is 2× the mechanical angle.

Note that at larger scan angles, the beam quality at the edges of the field lens may degrade.

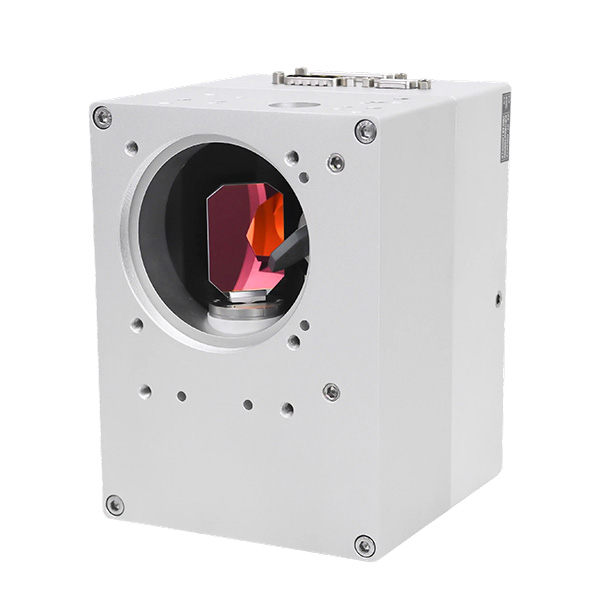

Galvo scanner

These parameters determine the “speed” and “agility” of a galvo scanner.

This is the speed during actual processing — the instantaneous linear speed of the laser spot as it moves across the material while engraving lines or patterns. If your application involves large-area fills or long-path engraving, high marking speed is essential for boosting throughput.

The maximum rotational sped of the galvo motor. It refers to how fast the beam can travel from the end of one marking point to the start of the next. Higher positioning speed reduces “dead time” when jumping between separate features. For jobs with many small, scattered features — such as micro-hole arrays or PCB coding — high positioning speed is critically important.

The time required for the galvo to move 1% of its full travel range and settle. This reflects the scanner’s ability to perform small, rapid angular jumps.

The time required for the galvo to move 10% of its full travel range and settle. This indicates the scanner’s ability to handle larger, longer-distance moves.

The difference — in time or angle — between the commanded position and the actual mirror position. A smaller tracking error means the galvo follows control commands more accurately, which is essential for high-precision marking.

2D galvo scanner(Galvo head)

These parameters determine the “precision” and “consistency” of a galvo scanner.

Linearity measures the maximum static deviation between the actual mirror position and the commanded position across the full travel range. It is usually expressed in milliradians (mrad). A smaller value indicates better linearity and less overall distortion in the engraved or marked pattern. This is a key indicator for high-precision micro-machining.

Repeatability refers to how closely the galvo can return to the same commanded position multiple times. It is typically measured in microradians (µrad). Higher repeatability (smaller values) ensures consistent results. For example, <2 µrad is considered a high-performance standard.

The proportional error between the actual deflection angle and the commanded angle.

The deviation of the mirror position when the command is zero.

Gain error and zero offset are inherent static errors of the system, usually correctable through calibration. Better factory specifications for these parameters mean more reliable out-of-the-box performance.

These parameters determine how stable a galvo scanner remains during prolonged operation or under changing environmental conditions.

These are all types of thermal drift, describing how the galvo’s gain (amplification factor) and zero position (reference point) change with temperature. Smaller values indicate that the system is less sensitive to temperature changes, resulting in better long-term stability. Thermal drift is a key factor distinguishing standard galvos from high-performance models, especially in industrial environments without temperature control.

This measures the slow change in mirror position over time under constant environmental temperature and power supply conditions. It reflects the internal stability of the system, independent of temperature.

Long-term drift is critical for equipment that requires continuous, high-precision operation over extended periods.

This is currently the most widely used and mainstream protocol. The controler card sends digital position commands to the galvo driver through a dedicated hardware interface and protocol. Developed by Cambridge Technology, it has become the de facto industrial standard. It uses a 25-pin parallel cable to transmit multiple digital signals. Compared to analog protocols, XY2-100 is far more reliable, with 16-bit resolution as standard, offering much higher accuracy and better compatibility.

In this method, the controller card outputs ±10 V or ±5 V analog voltage signals through a DAC (digital-to-analog converter) to directly control the galvo position. The voltage value corresponds to the target angle. This protocol is typically used in low-end, cost-effective laser marking machines or OEM applications where high precision is not critical.

Make sure the galvo scanner’s aperture and the laser’s wavelength/power match your laser source.

High-Precision Micromachining: Focus on linearity, repeatability, 1% full-scale response time, tracking error, and all types of drift. High-Speed, Large-Area Processing: Focus on marking speed, positioning speed, 10% full-scale response time, and aperture size. High Long-Term Stability: Pay attention to all drift-related parameters.

Ask the supplier about the testing conditions for key specifications, such as step response time and tracking error, to ensure you are comparing scanners under the same standards.