In the laser industry, achieving micron or sub-micron accuracy isn’t optional—it’s essential. Applications such as laser marking, micro-welding, semiconductor lithography, and precision micromachining demand that laser beams land exactly where intended, every single time. Behind this capability lies a critical enabling technology: the optical encoder.

An optical encoder converts mechanical motion (rotary or linear) into high-fidelity electrical signals, enabling closed-loop feedback for motion control systems. In modern laser systems, they function as the “eyes” that guide beam steering, stage motion, and path alignment.

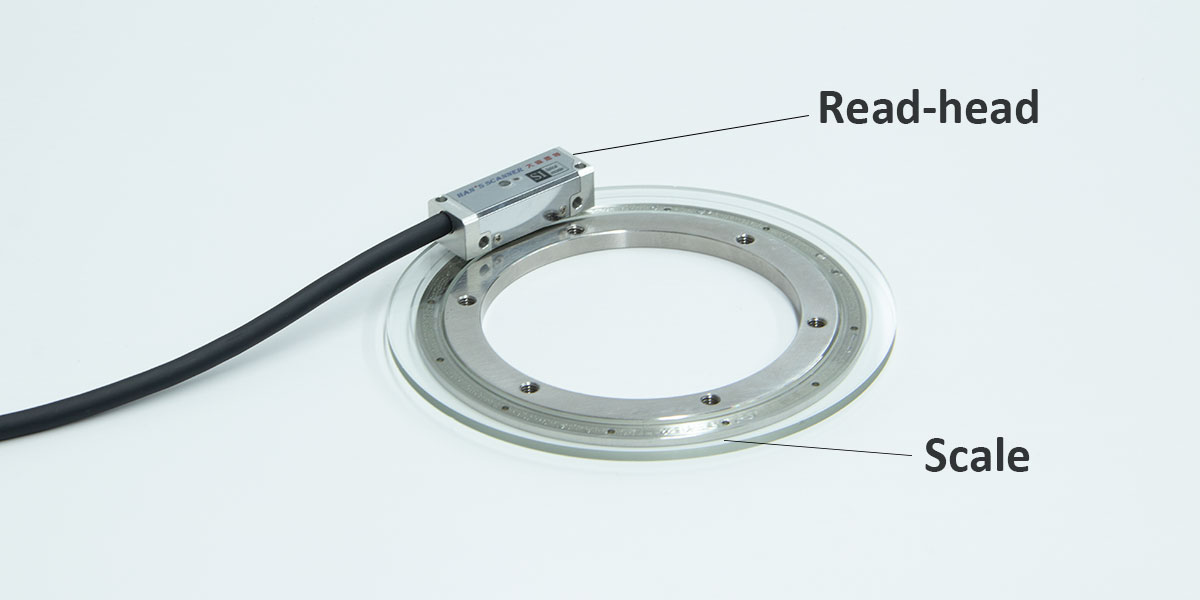

An optical encoder is a device that uses a light source, a coded scale, and photodetectors to measure position, angle, speed, or direction of a moving component. By transforming mechanical motion into electronic data, encoders allow laser systems to achieve micron or even nanometer-level accuracy.

Optical encoders typically consist of:

Light source (LED or laser diode)

Rotary disk or linear grating with coded patterns

Photodetectors to capture light interruptions

Signal processing electronics to convert signals into readable data

When the shaft or stage moves, the encoded pattern modulates the light, producing digital signals. These signals are then interpreted by the control system to monitor real-time position and speed.

Rotary Encoders – Integrated with galvo motors to monitor mirror angles in scanning heads.

Linear Encoders – Installed on precision stages for laser cutting, lithography, and semiconductor manufacturing.

Incremental Encoders – Output pulse sequences to indicate relative movement, ideal for high-speed scanning.

Absolute Encoders – Provide exact position values, ensuring accuracy even after power loss.

Laser Marking & Engraving – Encoders inside galvo scanners guarantee precise placement of text, barcodes, and logos.

Laser Cutting & Welding – Stage-mounted encoders control beam paths for clean cuts and consistent weld seams.

Additive Manufacturing (3D Printing) – Encoders synchronize layer alignment for reliable part accuracy.

Semiconductor & PCB Fabrication – Linear encoders achieve nanometer-level wafer positioning.

Laser Projection & Micromachining – Dynamic beam steering relies on encoder feedback to avoid distortion.

High resolution and accuracy for demanding processes.

Real-time feedback for stable beam steering at high speeds.

Non-contact operation, reducing mechanical wear and drift.

Scalable use cases, from compact galvo heads to large CNC platforms.

In modern laser galvo systems, optical encoders are the backbone of precision motion control. From galvo scan heads to semiconductor stages, they ensure that every laser beam is positioned with absolute accuracy and reliability.

At Scanner Optics, we provide advanced galvo scanner solutions designed with high-performance optical encoders for unmatched precision and efficiency.