In modern laser processing, the performance of the galvo scanner is crucial. It affects the accuracy, speed, and reliability of the system. Choosing the right setup for fiber, CO₂, or UV lasers helps create high-quality markings. It also speeds up production and keeps operations stable over time.

Different laser sources operate at unique wavelengths, which determine the required mirror coatings, laser scan lens, and driver settings.

Fiber laser galvos (1064 nm) are best suited for deep metal engraving, marking tools, and industrial components. They use dielectric or gold-coated mirrors to improve reflection and keep a strong beam during long marking tasks. These systems are common in labeling car parts, marking aerospace components, and engraving precision tools.

Engineers optimize CO₂ laser galvos (10.6 µm) for organic materials such as plastics, wood, leather, and paper. Gold-coated mirrors and IR-optimized laser scan lens ensure stable energy delivery and minimal distortion. Common applications include packaging marking, acrylic signage, decorative engraving, and large-area surface processing.

UV laser galvos (355 nm) are ideal for ultra-fine micro-marking on glass, ceramics, and PCBs. Using dielectric-coated optics, they maintain high transmission while minimizing thermal damage. Companies commonly use UV systems in electronics, IC packaging, and marking medical devices. They can create very precise details without causing melting or discoloration.

Selecting optics specifically designed for each wavelength is essential to prevent energy loss, surface burning, and inconsistent spot size.

When choosing a laser galvo, wavelength compatibility is only the starting point. Other critical factors include:

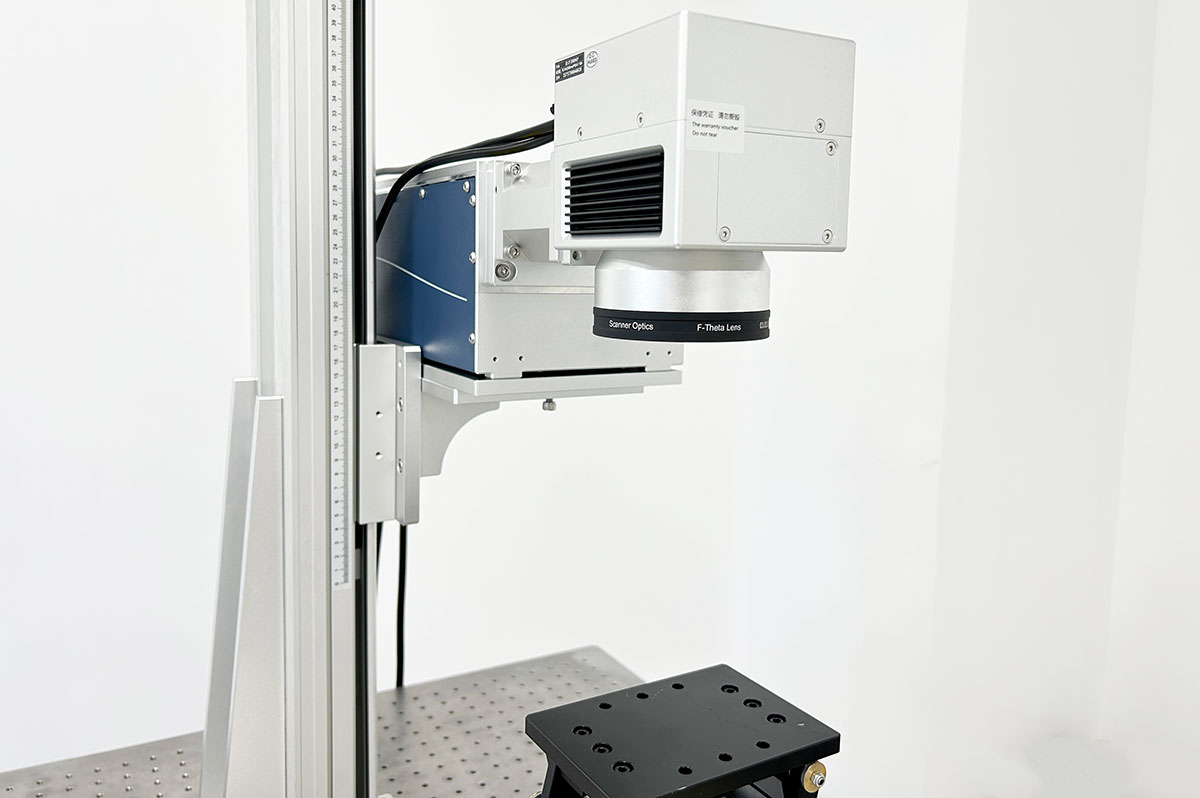

Scan Angle and Field Size: The maximum scan angle defines the marking area. Larger angles allow broader coverage but can slightly reduce spot precision. Combining mirror size with appropriate F-Theta lens focal length ensures optimal balance between field size and beam quality.

Speed and Mirror Inertia: High-speed marking requires low-inertia mirrors and high-bandwidth servo drivers. Closed-loop feedback systems keep precise positioning. In contrast, open-loop systems are more likely to drift and have positional errors, especially during continuous operation.

Cooling and Stability: Long-duration marking or engraving demands proper thermal management. Air or water cooling stabilizes mirror positions, prevents thermal drift, and extends the lifespan of both mirrors and motors.

Control and Integration: Modern galvos often use XY2-100 digital protocol for accurate communication with laser sources and design software. Integration with dynamic focusing modules allows real-time Z-axis adjustments, ensuring uniform marking on 3D surfaces.

Optical Quality: Selecting the correct F-Theta lens is vital. Shorter focal lengths enable finer spot sizes for small details, while longer focal lengths support larger scan fields. Lens coatings must match the laser wavelength to reduce energy loss and avoid thermal distortion.

Laser galvo systems are now integral to many industrial and commercial applications:

Fiber Laser Galvos: Ideal for high-speed metal marking, serial numbers, barcodes, and deep engraving. Automotive manufacturers use fiber laser galvo to mark aluminum engine parts, while tool manufacturers label industrial cutting tools for traceability.

CO₂ Laser Galvos: Common in packaging, signage, and decorative engraving. Manufacturers often process acrylic signs, wooden products, and leather goods using CO₂ galvos for precise cutting and aesthetic engraving.

UV Laser Galvos: Best for micro-marking, PCBs, semiconductors, and medical devices. One case involved a medical device producer marking serial codes on white plastics.

The UV system’s fine beam spot prevented melting or discoloration. The dielectric F-Theta lens kept a steady focus across the whole work area. This led to better clarity and almost no scrap rate compared to fiber-based options.

Using the correct galvo system for each application ensures efficiency, precision, and minimal waste in production.

The laser galvo industry continues to evolve with innovations enhancing performance and versatility:

Multi-Wavelength Systems: Allow processing of different materials using one platform, reducing the need for multiple machines.

AI-Assisted Path Optimization: Algorithms adjust mirror speed and laser power dynamically based on pattern complexity, increasing throughput and accuracy.

3D Dynamic Focusing Modules: These modules sync mirrors with a moving lens. They keep a steady spot size and energy density on uneven surfaces. This makes them great for additive manufacturing, surface texturing, and complex welding.

Compact and Embedded Galvo Head: Smaller galvo head makes automation easier. They allow for fast marking in robotic arms and production lines.

Closed-Loop Feedback Enhancements: Next-generation sensors provide ultra-high positional accuracy, reducing drift and improving repeatability over long production cycles.

These trends position laser galvos as essential tools for high-speed, high-precision industrial marking and microfabrication.

1: Is it possible for one galvo scanner to work with different laser types?

No. Different wavelengths require specific mirror coatings and lens materials. Using the wrong galvo can cause power loss and optical damage.

2: How can we maintain precision over time?

Stable mounting, proper cooling, and periodic calibration are essential. Closed-loop feedback systems greatly reduce drift.

3: What is the typical lifespan of a laser galvo?

Industrial-grade galvos generally last 10,000–20,000 hours, depending on operating conditions and maintenance.