Traditional 2D galvo scanning systems are limited by their optical design and can only operate within a working area of a few tens to a few hundred millimeters. An XY stage alone can achieve large-area processing, but it is slow, inefficient, and prone to stitching errors. By synchronizing a 2D galvo scan head with an XY stage, a practical “Infinite Field of View” IFOV can be achieved, effectively overcoming the challenges of large-format laser processing.

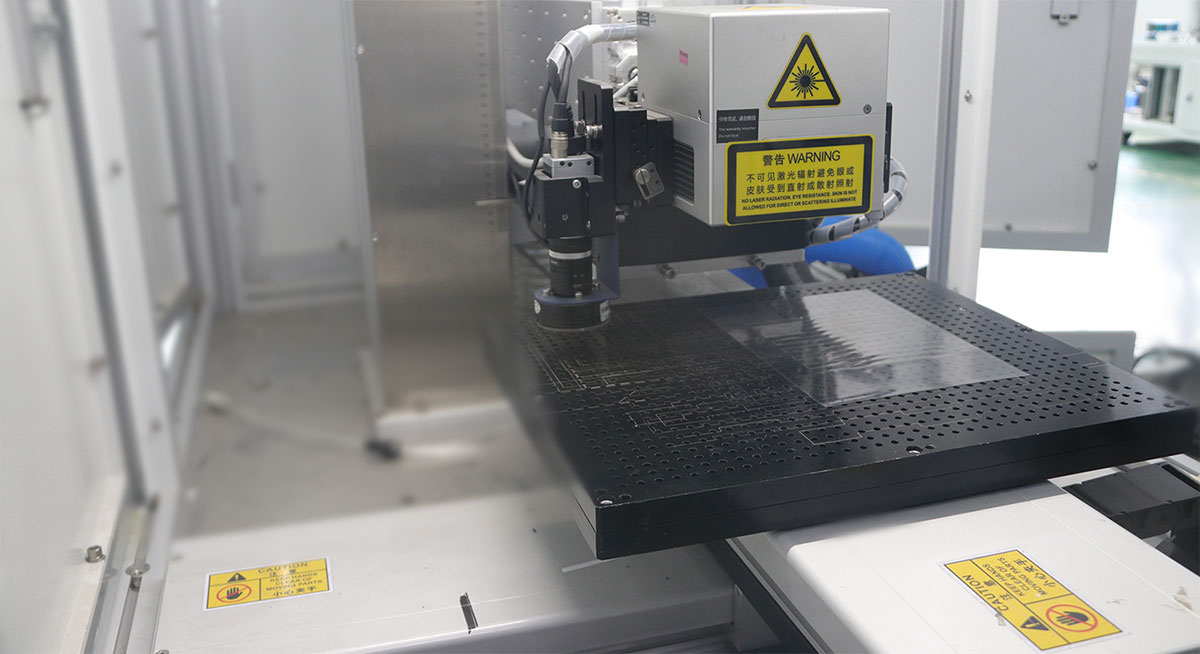

IFOV System Demo

A 4-axis infinite field of view system typically consists of the following four components:

XY Galvo Head responsible for high-speed scanning of fine trajectories, featuring high precision and fast response.

XY Motion Platform/Driver used to achieve large-area movement, extending the processing range to hundreds of millimeters or even meters.

GMC Controller uses advanced algorithms to place the galvo and platform in the same coordinate system, achieving seamless processing.

Laser Processing Software sets laser parameters, generates processing trajectories, and controls the galvo and laser to perform marking or other processing operations.

The IFOV 4-Axis system integrates an XY scan head, an XY motion platform, a platform driver, a GMC controller, and customized processing software. It has Infinite Field of View processing function and can synchronize the XY motion platform and scan head. The combination of scan head with high dynamic performance and the XY motion platform with large stroke range solves the problem of limited machining range of traditional 2D galvo scanning system, and there is no stitching error, which is suitable for large-size and high-precision laser machining apolications.

|

|

| XY Galvo Head | XY Motion Platform/Driver |

|

|

| GMC Controller | Laser Processing Software |

In laser processing, the optical design of a scan head usually limits the scanning arae. For very large workpieces, traditional methods are slow due to segmented (tiled) processing. A 4-axis synchronized system can extend the working area virtually without limits.

Because the galvo head always operates within its optimal optical field, the system maintains consistent spot size, energy density, and micron-level accuracy—even when processing extra-large parts. This enables fine laser processing, including marking, cutting, and other operations, significantly improving production efficiency.

With 4-axis synchronization, there is no need to segment large-area workpieces. The system can process the entire pattern seamlessly, eliminating stitching errors that occur near the edges of the scanning field.

During large-area processing, the smooth motion of the platform keeps the galvo continuously engaged, increasing throughput and improving both processing quality and productivity for large parts.

The 4-axis IFOV system is widely used in advanced glass processing applications. It enables high-uniformity surface frosting/matting, precise micro drilling, and efficient cleaning or paint removal on large or irregular glass panels.

Flexible OLED panels require consistent spot quality and precise trajectory control. The IFOV system maintains uniform cutting quality across large panels. It is ideal for processing flexible materials and ultra-thin glass, improving yield, and can be integrated into large-scale mass production lines.

Flexible printed circuits (FPCs) are large in size and thin in thickness, making them prone to edge distortion with conventional scanning systems. The IFOV architecture assigns detailed scanning to the galvo and large-area movement to the platform, synchronizing both for high-speed, distortion-free cutting. It efficiently handles multi-layer structures, irregular shapes, and batch layouts, maintaining clean cut edges and precise contours even on large panels.

The IFOV 4-Axis solution bridges a long-standing trade-off in laser processing and scanning systems: traditionally, one had to choose between small spot size & high precision over small area (galvo) or large area coverage & low throughput with XY-stage. The IFOV architecture removes that trade-off — delivering high precision + large coverage + high throughput all in one system.

If you’d like to learn more, please visit our 4-Axis Large Field Processing System.