Laser drilling is a precision manufacturing process that uses a highly focused beam of light to remove material and form holes in a wide range of substrates. Unlike mechanical drilling, it is a non-contact method, meaning there is no physical tool wear or mechanical stress on the part.

When combined with a galvo scanner, laser drilling becomes significantly faster, more flexible, and more efficient — enabling manufacturers to perform micro drilling and macro-scale hole processing with exceptional accuracy and repeatability.

A galvo scanner uses high-speed mirrors driven by galvanometer motors to direct the laser beam across the workpiece. Instead of moving the entire part or the laser head, the galvo system redirects the beam within milliseconds, allowing for rapid beam positioning and precise drilling control.

High-Speed Beam Steering: Enables fast, precise drilling at high repetition rates.

Superior Accuracy: Maintains uniform hole spacing and shape across large working fields.

Flexible Processing: Supports pattern drilling, array drilling, and variable hole geometries.

Non-Contact and Wear-Free: Eliminates tool wear common in mechanical drilling.

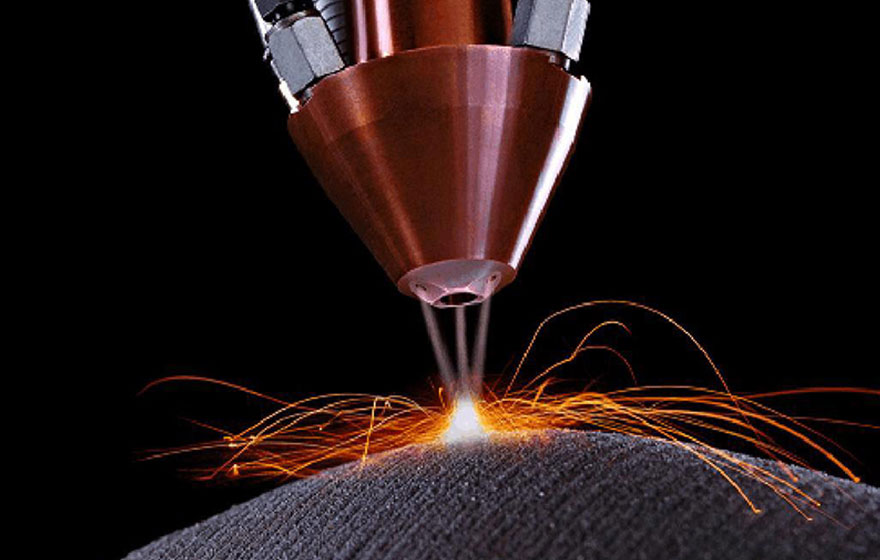

Beam Focusing – The laser beam is focused through a galvo scan lens onto the material surface.

Energy Absorption – The localized laser energy melts or vaporizes the material.

Material Ejection – The molten or vaporized material is expelled, forming a hole.

Galvo Movement – The galvo mirrors reposition the beam to the next drilling point, repeating the process rapidly.

This setup ensures stable, repeatable drilling performance even in large-area or multi-hole applications.

| Technique | Description | Typical Application |

| Single-Pulse Drilling | A single laser pulse removes material to form a hole. | Micro-hole drilling in thin foils or films |

| Percussion Drilling | Multiple pulses at one location deepen the hole. | Multi-layer or thick materials |

| Trepan Drilling | The beam moves in a circular path for larger holes. | Nozzles, filters, precision mechanical parts |

| Helical Drilling | Beam and workpiece rotate simultaneously for deep, high-aspect-ratio holes. | Turbine components, aerospace alloys |

Laser drilling systems with galvo scanners are widely used in industries requiring high-speed precision and complex hole arrays.

| Industry | Typical Use |

| Aerospace | Cooling holes in turbine blades and combustor liners |

| Electronics & Semiconductors | Micro-vias and interconnect holes in PCBs and wafers |

| Medical Devices | Micro-needles, catheter holes, precision filters |

| Battery & Energy | Vent holes in electrodes and casings |

| Automotive & Engineering | Injector nozzles, sensor components, and filter meshes |

| Feature / Aspect | Galvo Laser Drilling System | CNC Drilling |

| Processing Speed | Extremely fast beam steering — typically hundreds of holes per second | Limited by mechanical motion — usually a few holes per second |

| Precision & Repeatability | Sub-micron beam positioning accuracy; consistent hole quality | Dependent on tool wear and mechanical backlash |

| Contact Method | Non-contact, no tool wear or deformation | Physical contact causes tool wear and maintenance |

| Hole Size Range | From micrometers to millimeters | Generally limited by drill bit size and tool design |

| Material Compatibility | Works on metals, ceramics, glass, polymers, and composites | Mainly suitable for metals and plastics |

| Automation & Control | Easily integrated with software, vision, and galvo control cards for automated drilling patterns | Requires mechanical repositioning and manual setup |

| Thermal Effect / Damage | Minimal heat-affected zone due to short pulse duration | Possible burrs, cracks, or heat stress on edges |

Compared to traditional CNC drilling, galvo-based laser drilling systems offer higher precision, speed, and flexibility, especially for micro-hole and large-array processing applications.

Laser drilling with galvo scanners represents the future of precision hole processing — combining the power of laser energy with high-speed digital beam control. As industries move toward automation and miniaturization, galvo-based laser drilling systems continue to provide unmatched flexibility, speed, and process reliability.

In addition to processing standard straight holes and conical holes, the 5-axis laser micromachining system independently developed by Scanner Optics can also create inverted conical holes, greatly expanding the scope of laser drilling applications. By using different wavelengths and ultra-fast lasers, the system minimizes the heat-affected zone, produces smooth surfaces, and supports a wide variety of materials. This flexibility makes it suitable for drilling across numerous industrial sectors, enabling truly universal laser drilling solutions.