With the rapid growth of the electric vehicle (EV) industry, battery manufacturers are facing higher requirements for welding precision, surface treatment, and overall production efficiency. Ensuring both safety and consistency in battery modules has become a critical challenge. As key players in the laser industry, Raycus Laser, with its advanced high-power laser sources, and Scanner Optics, with its high-speed galvo scanner systems, are jointly providing validated solutions for efficient EV battery production.

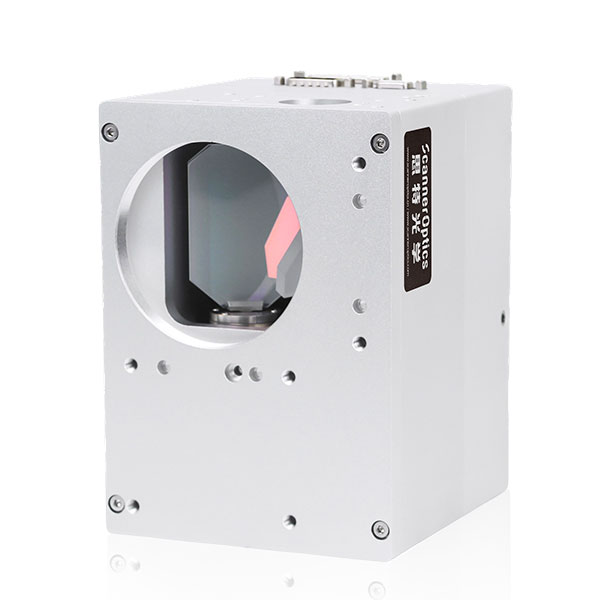

In EV battery welding, the combination of Raycus high-power lasers, Scanner Optics high-performance laser welding systems, and precision F-Theta scan lenses ensures stable and consistent processing results.

Battery tab welding: Using a 4+2 ring laser configuration with galvo-controlled scanning, the solution achieves uniform weld seams with spatter reduction of up to 40% compared to conventional systems.

Nickel sheet welding: Raycus 1500W and 3000W single-spot lasers, paired with Scanner Optics’ laser welding systems, provide strong, repeatable welds. Tensile strength tests show an improvement of 15–20%, meeting the stringent requirements of ISO 26262 functional safety standards for automotive applications.

This integrated laser welding system is already being evaluated by tier-1 EV battery module manufacturers in China and Europe, demonstrating both scalability and production readiness.

During battery assembly, insulation blue films are applied to protect cell surfaces. Defective films must be removed efficiently without damaging the aluminum housing.

The Raycus 1000W nanosecond pulsed laser combined with Scanner Optics high-speed 20mm galvo head provides:

Flat-top or square laser spots for uniform removal.

Controlled thermal input with <10°C temperature rise, verified through thermal imaging analysis.

Cleaning rates exceeding 300 mm²/s, ensuring high throughput while maintaining substrate integrity.

This process has been validated in pilot production lines and offers a significant reduction in scrap rates compared to mechanical cleaning methods.

Surface preparation is essential for improving weld strength, electrical conductivity, and coating adhesion. Traditional methods such as grinding or chemical etching face issues of low efficiency, environmental impact, and poor precision.

Laser texturing with galvo scanners provides a superior alternative:

Raycus 1000–2000W nanosecond pulsed lasers, integrated with Scanner Optics 30mm galvo head, achieve highly uniform surface roughening.

Square beam spots reduce overlap rate, ensuring consistent textures with roughness (Ra) controlled within ±0.5 µm.

High-speed scanning minimizes substrate damage, supporting improved bonding strength and extended battery cycle life.

By combining Raycus high-power laser technology with Scanner Optics high-performance galvo laser systems, manufacturers can achieve highly efficient, precise, and reliable processes for EV battery welding, cleaning, and surface texturing. These integrated solutions not only meet the stringent requirements of modern electric vehicle battery production but also comply with ISO/IEC laser safety standards.