Galvo scanners are high-precision motion control devices widely used in laser scanning systems. In laser applications, galvo scanner utilizes mirror-based technology to control the direction of laser beams by rotating and adjusting the mirror angles within a defined work area. They are commonly applied in laser marking, medical imaging, 3D printing, and more. Based on their internal structure and feedback mechanism, galvo scanners are mainly categorized into photodetector-based and encoder-based types. This article provides an in-depth analysis of the technical features, application scenarios, and selection guidance for both types of galvo scanners.

In laser processing, precision and repeatability depend largely on how accurately the galvo mirrors move. Even a slight feedback error can cause misaligned markings, blurred edges, or reduced throughput. To ensure stable performance, galvo scanners integrate feedback systems—mainly photodetector-based or encoder-based—to monitor and correct mirror positions in real time. Understanding the differences between these two feedback mechanisms is essential for choosing the right galvo scanner for specific application requirements.

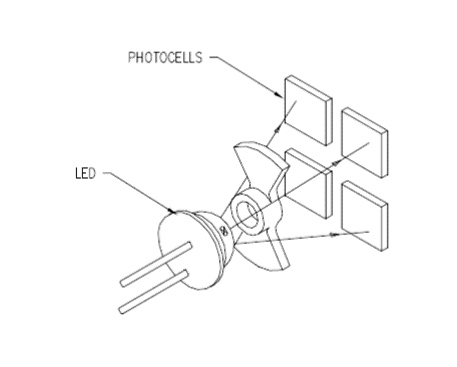

Photodetector-based galvo scanners are high-precision angular control devices composed primarily of a moving magnet rotor, a coil stator, and a photodetector position sensor. Their core operating principle is based on an energized coil driving the rotor, while the photodetector provides real-time feedback on the rotor's position to achieve closed-loop control through a driver circuit.

Electromagnetic Drive: The coil in the stator generates an Ampere force when current flows through, which drives the rotor and attached mirror to oscillate at high speed within a limited angular range.

Photodetector Feedback: A silicon photodetector detects the rotor position. For example, as a light-blocking component rotates with the rotor, the illuminated area on the photodetector changes, generating an electrical signal proportional to the angle. This signal is fed back to the controller to calibrate position.

Compact design and cost-effective

Excellent precision and speed performance, suitable for mid-to-high-end markets

Position resolution can reach less than 2 µrad

Photodetector structure illustration

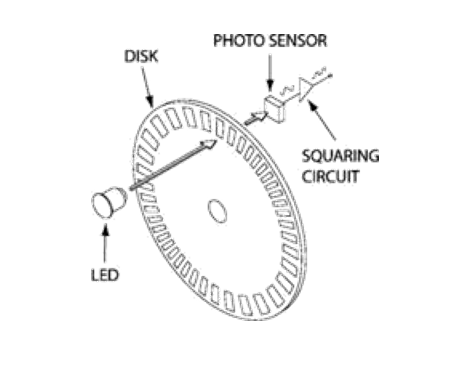

Encoder-based galvo scanners use optical encoders for high-precision position detection and combine with digital drive technology to enhance overall performance:

Optical Encoder: Based on optical diffraction principles, these encoders have evenly spaced grating lines etched on glass or metal. They convert light signals into electrical signals with resolutions reaching the nanometer level.

Closed-Loop Control: The encoder provides real-time rotor angle feedback. Paired with digital control boards (e.g., FPGA-based systems), they achieve micro-radian positioning accuracy with dynamic tracking error below 0.12 ms.

Structural Optimization: SCANNER OPTICS has independently developed a 23-bit optical encoder and high-density coil winding that reduces motor size while increasing response speed, making it ideal for high-speed environments.

High precision and resolution: Direct angle displacement measurement, significantly higher than photodetector-based sensors

Strong anti-interference: Digital signal processing suppresses environmental electromagnetic interference for stable performance

Low thermal drift: Minimal performance impact from temperature changes

Digital interface: Easy integration with digital control systems

Higher cost and technical complexity

Digital encoder structure illustration

| Feature | Photodetector-Based Galvo | Encoder-Based Galvo |

| Feedback Type | Analog | Digital |

| Resolution | Low to Medium | High (up to 23-bit) |

| Accuracy | Moderate | Excellent |

| Thermal Drift | Noticeable | Minimal |

| Response Speed | Very Fast | Fast |

| Cost | Lower | Higher |

| Applications | High-speed marking, engraving | Welding, 3D printing, precision machining |

For applications requiring cost efficiency and high throughput, photodetector-based galvos are sufficient. However, when precision, repeatability, and long-term stability matter—such as in battery tab welding or semiconductor packaging—encoder-based systems deliver superior results.

Due to differences in performance and load capacity, various galvo scanners are suited to different application scenarios:

1. Photodetector-Based Galvo Scanners :

Widely used in ophthalmic OCT imaging, confocal microscopy, medical handpieces, laser projection systems; general laser marking, FPC and film cutting, wafer dicing and slotting, and laser cleaning.

|

|

| Ophthalmic OCT Devices | Laser Projection Devices |

|

|

Confocal Microscope | Aesthetic Fractional Laser Systems |

|

|

| FPC Cutting | Metal Surface Marking |

|

|

Film Cutting | Laser Cleaning |

3. Encoder-Based Galvo Scanners:

Ideal for lithium battery tab welding, precision drilling, additive manufacturing (3D printing), and inspection and metrology applications.

|

|

| 3D Printing | Glass Drilling |

Both photodetector and encoder feedback technologies have their place in modern galvo scanners. Photodetector galvos provide a compact and cost-effective solution for high-speed marking and engraving. Encoder-based galvos, on the other hand, deliver superior accuracy, stability, and long-term reliability, making them ideal for advanced manufacturing and welding systems.

Whether you’re developing a new laser workstation or upgrading an existing platform, Scanner Optics offers tailored galvo solutions to match your performance goals.